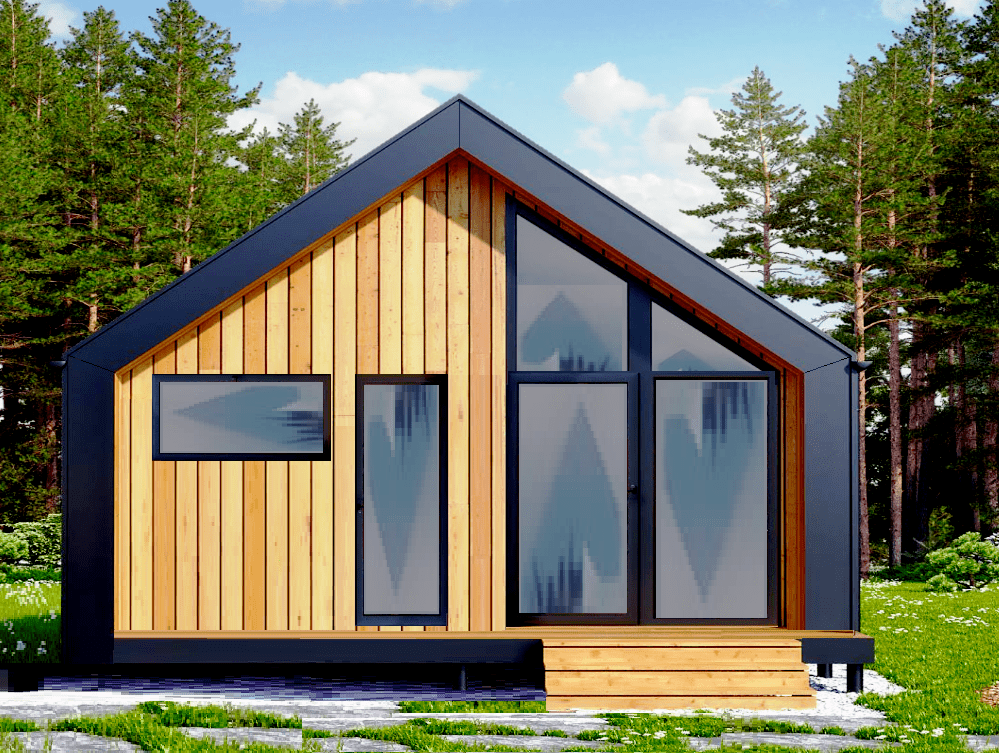

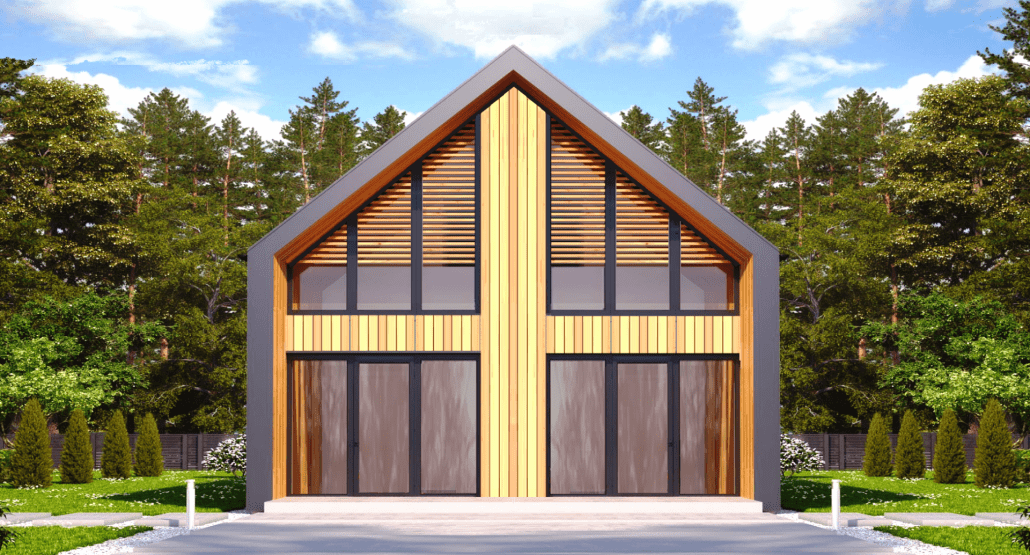

European Prefabricated Houses with Steel Frame

Description

Thin sheets of galvanized steel can be cold formed into steel studs for use as a structural or non structural building material for both external and partition walls in both residential, commercial and industrial construction projects. The dimension of the room is established with horizontal track that is anchored to the floor and ceiling to outline each room. The vertical studs are arranged in the tracks, usually spaced 40cm apart, and fastened at the top and bottom.

The typical profiles used in residential construction are the C-shape stud and the U-shaped track, and a variety of other profiles. Framing members are generally produced in a thickness of 12 to 25 gauge. The wall finish is anchored to the two flange sides of the stud, which varies from 1-1/4" to 3" thick, and the width of web ranges from 1-5/8" to 14". Rectangular sections are removed from the web to provide access for electrical wiring.

Steel mills produce galvanized sheet steel, the base material for the manufacture of cold formed steel profiles. Sheet steel is then roll-formed into the final profiles used for framing. The sheets are zinc coated (galvanized) to prevent oxidation and corrosion. Steel framing provides excellent design flexibility due to the high strength to weight ratio of steel, which allows it to span over a long distances, and also resist wind and earthquake loads.

Steel framed walls can be designed to offer excellent thermal and acoustic properties - one of the specific considerations when building using cold formed steel is that thermal bridging can occur across the wall system between the outside environment and interior conditioned space. Thermal bridging can be protected against by installing a layer of externally fixed insulation along the steel framing - typically referred to as a 'thermal break'.

The spacing between studs is typically 16 inches on center for homes exterior and interior walls depending on designed loading requirements. In office suites the spacing is 24 inches on center for all walls except for elevator and staircase wells.

Specifications

Area: from 120 m2 up to 450 m2

Scope: design with all trades / execution / materials procurement

Steel is 100% recycled and recyclable, without losing its properties. The steel used in the formation of the structure 80% comes from recycling (source: Arcelormittal).

Minimize the use of steel. Ratios kg/m2 edification are, for this system, extremely low, around 24 to 30 kg/m2 edification.

Virtually no construction waste is generated. The whole structure will be cut to size work.

Reduction of needed energy for the building due to high degree of thermal insulation of walls & roofs

"Dry" system, no consummation of water / Low weight constructive system / reduction of transport impact

No need for heavy machinery / reduction of time implementation / reduction for neighbors inconvenience & environment impact.

The structure of STEEL FRAMING, as already mentioned, is formed by a group of steel properly joined together. These profiles are obtained by profiling (possibly folded) steel sheet thickness between 0.6 mm and 3.5 mm and DX51D + Z275N SPANISH (according to EN10142 standard) with a minimum yield strength of 250 N/mm2 and a resistance minimum tensile strength of 330 N/mm2.

Protection against corrosion of steel is achieved by a hot dip galvanized Z275N type, with a zinc coating of 275 g/m2 on both sides.

Resistant elements, Galvanized steel / low thickness, obtained by a process of cold forming.

Galvanized steel made in cold and joined by means of self drill screws.

Possible to use infinity of different sections, optimizing the structure and allowing all kinds of architectural .

configurations without limitations of form in this way.

All types of Interior & Exterior finishes can be applied over waterproof panels.

The construction system can be used in buildings up to 4 floors (GF + 3 Levels)

- Country of origin: Spain

- Representation: Exclusive

- Since: 2001